Photo slideshow by Matthew Worden

Want to see more photos from Washington events and parties? Click here for Washingtonian.com's photo slideshow page.

Paul Reed Smith went from wannabe musician repairing other people’s guitars to being one of the world’s most sought-after guitar makers. Big names like Carlos Santana and Al Di Meola have been among his customers for years. The US Supreme Court recently took his side against a famous guitar maker.

Put all that on hold. What Smith wants to talk about is where it all started: with the music.

Smith leans across the table, his eyes boring into a visitor like one of the high-tech routers that cuts contours into wood in the factory next door.

“You’ve got Chuck Brown and the entire go-go thing,” he says. “You’ve got the Nighthawks and Roy Buchanan and the whole blues thing. You’ve got the jazz-rockabilly-blues thing that Danny Gatton did. Then the jazz scene in Baltimore, and one of the best top-40 scenes ever. It just goes on and on. You could go into DC and hear amazing amounts of music.”

Smith, who was born in Rockville and grew up in Bowie, did it as often as he could, usually sneaking into clubs until he turned 18. At one—a strip joint—he would arrive early. “I had to sit downstairs at the bar and watch the girls strip and then go upstairs to watch the band when they started playing.”

Smith wanted to play guitar in a band. But first he had to learn how.

“I learned in the Bayou,” he says, recalling the Georgetown club that gave acts like U2, Dire Straits, Stevie Ray Vaughan, and many others their first Washington gigs. “My whole life has been about getting mentored by the older guys, so I’d go down there and watch Sinbad or Cherry Smash”—popular area bands during the ’70s—“and beg ’em to let me sit in.”

Smith immersed himself in the world of guitar rock in Washington. He played in bands, forming friendships that still exist. But the strongest bond is with the Bayou.

“There’s the scene in that Kevin Costner movie, No Way Out, when he jumps off the Whitehurst Freeway,” Smith says. “He jumps onto the roof of the Bayou! I’m screaming in the theater, ‘That’s the roof of the Bayou!’”

Getting into the Bayou was just one of the breaks Smith created for himself through determination and passion, both fueled by the energy of the area’s music scene.

Some guitars look great, others sound great, still others feel great. Some share two of those qualities, but few possess all three, and there are people who will say none has them to the degree found in a PRS—Paul Reed Smith’s line of guitars.

“There’s such a fanatical level of attention to detail that goes into making a PRS,” says Brian Meader, assistant manager at Chuck Levin’s Washington Music Center in Wheaton, where Smith worked when he was starting out. “It’s more an art with Paul. It’s not just a product stuck in a box.”

The National Museum of American History has a PRS with a mother-of-pearl dragon inlay along the fretboard. Howard Leese, whose PRS powers the hard rock of the group Heart, has called Smith “the American Stradivari of the electric guitar.”

Tom Wheeler sensed as much two decÂades ago, when he was editor of Guitar Player magazine and got a call from someone raving that a guitar he’d bought called a PRS blended the best of instruments made by Gibson and Fender, the longtime leaders of American guitar making.

“Oh, great,” Wheeler thought, assuming that Smith, like others before him, probably had slapped some of Gibson’s electronics into a Fender-style body. “But when I saw the guitars and held them,” Wheeler later wrote, “I understood that the new guy, whoever he was, was on to something much more profound.”

The editor of a magazine that receives scores of guitars each year for review believed he was holding “the handiwork of a deeply insightful craftsman who had absorbed to his very marrow the essence of the modern electric guitar and reinterpreted it for a new era.”

The tonal range of the instrument ultimately won over a similarly skeptical Carlos Santana, who once said, “To me the sound of guitars is like colors. With some you get just green and yellow. This guitar is like the full rainbow.”

The glasslike finishes—some involving ornate decoration with 12 kinds of shell, five types of reconstituted stone, and mastodon ivory—along with the carefully cured woods and hand-wired electronics have put PRS guitars in a class alongside the best of Gibson’s and Fender’s.

“For Paul to have become one of the Big Three is a huge thing,” Meader says.

Paul Smith got the first inkling of what he would do with his life his senior year at Bowie High School. “In the beginning I didn’t have enough money to go to Chuck’s and buy a guitar,” he says. “Anytime I wanted anything and didn’t have the money, I’d build it myself.”

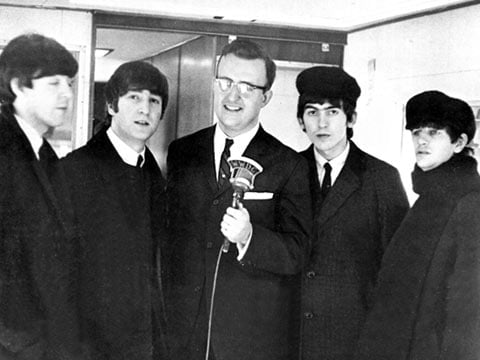

In shop class, Smith removed the neck from a Japanese knockoff of a Hofner Beatle bass and made a new body for it, recounts author Dave Burrluck in The PRS Guitar Book . From that beginning, he started looking at how guitars are put together. He repaired a friend’s guitar and showed it to the head repairman at Chuck Levin’s, who hired him.

After graduation in 1974, he went to St. Mary’s College, where he planned to major in math—his father was a mathematician for the Navy, his mother taught math at Yorktown Elementary in Bowie. But Smith lasted only 18 months in college before realizing he wanted to make guitars for a living.

In his last semester on campus, he made a deal with a music professor: In return for four academic credits, Smith would buy wood from a violin maker and make a guitar. “I built my first ‘real’ guitar in the basement of the art building,” he told BurrÂluck. Resembling a Gibson single-cutaway Les Paul Jr. model, it’s now on display in the entrance hall of the PRS factory.

Smith had no formal training in guitar repair, so he sought advice from Joe Wallo, who ran a violin shop in DC and had a side business selling guitar parts. Smith befriended him and learned the basics of the craft.

Soon Smith was making guitars and selling them. Then he noticed something. “If I took a guitar I made into Chuck’s and opened the case, people came and looked,” he says. “If I sat down and played it, people ran away—well, not quite, but close. The guitar playing wasn’t as good as the guitar making, so I had to make a decision.”

After dropping out of St. Mary’s, Smith moved back in with his parents and began building and repairing guitars in his bedroom. Then he opened a repair shop in Annapolis. He continued to play, even pulling a stint as part of Root Boy Slim’s Sex Change Band, but repairs paid the rent. He developed a reputation as the repairman of last resort. “There were guys who’d had their guitars repaired so many times elsewhere that the frets wouldn’t hold any more, so they’d come and see me,” he says.

Danny Gatton and other top local players were among his clients.

Between repairs, he made guitars and sold them. As his work improved, he thought about how to make an electric guitar that could compete with the name brands. Many players often switched guitars during performances, typically alternating between a Fender Stratocaster and a Gibson Les Paul, two legendary instruments with distinct sounds. He studied vintage guitars and noticed details in craftsmanship that had all but disappeared by the mid-1970s.

Smith wanted to make one guitar that could provide the tones of both a Strat and a Paul and would have the look, feel, and playability of a vintage instrument. And he wanted his guitars to be beautiful. “People take in about 80 percent of information through their eyes,” he says. The combination meant high-quality woods and electronics and lots of handcrafted work.

Ideas for finishes sometimes happened by accident: Raw wood arrived with a green stain on it, so to hide the stain, Smith and his partner painted the whole guitar green. Eventually, he and his collaborators were inspired by the rainbow, hence the array of colors available on PRS guitars now.

Bird inlays on the neck, another signature touch, appeared early on. His mother was a bird watcher, which led him to buy a field guide to birds. He patiently learned to cut the inlays along the fretboard by hand.

To sell his guitars, Smith came up with an unusual marketing plan: He would take them to concerts given by touring big-time players, persuade the roadies to let him show a guitar to the star, then try to persuade him to buy it. What better advertising than to have a famous rocker slinging a PRS in front of fans and photographers?

It sounded naïve—borderline nuts. But it worked. Smith managed to get through to Ted Nugent after a show the Motor City Madman put on here in 1975. Nugent commissioned Smith to make him a guitar. Before delivering it, Smith saw that Peter Frampton was coming to town. Smith got in to see Frampton and showed him the Nugent guitar. Frampton commissioned one.

A few months later, with the finished Frampton guitar in hand, Smith headed for the now-defunct Capital Centre in Landover, where one of his idols—Carlos Santana—was to play a double bill with the progressive band Return to Forever. The plan was the same: Show the roadies the guitar, make it clear he wasn’t out to murder the artist, and get a backstage pass.

This time the roadies for Return to Forever were so impressed with Smith’s guitar that they made him show it to their guitarist, Al Di Meola. He commissioned a guitar.

Smith finally got to Santana, and the two jammed together backstage. But Santana didn’t order a guitar.

“I was devastated,” Smith recalls.

The star liked the feel of the guitar but not the sound. Smith knew the problem was the pickups—the metal bars on the guitar body that convert vibrations from the strings into electric signals for amplification. “I literally begged him to let me give him different pickups,” Smith recalls. “He was very nice but kept saying, ‘No, no.’ ”

Four years later Santana came back to play the Merriweather Post Pavilion. The roadie told Smith no dice—the guitarist wouldn’t see him. Undaunted, Smith handed the roadie a new guitar—with different pickups—and asked him to take it to Santana. A few minutes later the roadie returned and led him backstage, where Santana was playing. He asked if he could use it for the show.

Smith said yes. But he wanted Santana to commission one from him. “If you don’t fall in love with the instrument, you don’t have to pay for it,” Smith told him. “And Carlos said, ‘You mean if I don’t like, I don’t pay?’ And I said, ‘No, if you don’t fall in love with it.’ ” If he did, the guitarist would owe him $2,000, at the time a large sum.

When Santana got his guitar, he loved it—and paid, Burrluck recounts. But he wasn’t convinced the guitar was anything more than “an accident of God.” He commissioned a second, loved it, paid again—and called it “another accident of God.” The same thing happened with the third. It wasn’t until the fourth commission, for a double-neck guitar—a six-string neck and a 12-string neck attached to one body—that Santana began to think maybe the guy from DC knew what he was doing.

“Carlos made me earn his respect,” Smith says. “He does not give it.”

By 1985 Smith was ready to go national. With the help of an investor he formed a limited partnership, raising $500,000 in capital, and PRS Guitars was born. But even with a week’s worth of orders that totaled more than $300,000, not to mention having several boldface guitarists using his product, PRS Guitars was largely unknown.

Then in 1986, Guitar Player ran its first review of a PRS. Writing in the April issue, acclaimed luthier Rick Turner declared, “Smith has put a lot of hard work and love into producing a guitar he believes in. I believe in it, too; I have not played an electric guitar I liked better and very few I liked as much, including ones I have made myself.”

With that, Paul Smith, who used to sweep the floors at Chuck Levin’s, became PRS, a guitar-industry phenom who would that year for the first time show more than $8,000 in income on his federal tax return.

The PRS Guitars factory is in Stevensville, Maryland, on Kent Island just across the Chesapeake Bay Bridge from Annapolis—probably not the first place you’d think of as corporate headquarters for a major player in the music business. Smith wouldn’t argue.

“This is the worst state in the union to make guitars,” he says. Shifting humidity levels can wreak havoc on raw wood. “It’s zero percent in winter and 100 percent in summer, and it rains and it snows, and then it’s wet and then dry. There’s something we have to do to the air every minute just about.”

So why stay? “It’s home. My roots are here. You’re gonna have to get me out of here with a crowbar.”

The 205 or so people he employs are happy about that. More than a few are guitarists, usually working in jeans and T-shirts. Last year they made and sold about 12,000 guitars. And they’re gearing up to make and sell even more. Smith is adding 100,000 square feet to the factory complex—roughly quadrupling its size.

A regular PRS model retails for around $3,000, but discount deals can lower the price to under $2,000 for some models. Depending on things like quality of finish and hardware, you can easily get into five figures for custom instruments. A Korean manufacturer is licensed to make the PRS SE, a budget line with prices under $750. About 8,000 were produced in 2005.

In 1985, Smith started with two models; now he makes 15 “with a pile of iterations.” But the process hasn’t changed much.

“The woods we use are still the typical woods used in guitar making—mahogany, maples, rosewoods, spruces,” he says. “Calculating fret positions and inlays used to be done by hand, but now by computer. But it’s still pretty much a hand operation.”

Precision machines cut and size the woods after they’ve been dried, but then many hands take over—to sand, fit, assemble, and test parts. Anyone along the line can send a piece back if it doesn’t look or feel right. Applying and buffing finishes is an art in itself. At the end of the line, every guitar is plugged in and given a workout to make sure all systems perform. Rare is the defect or customer complaint, says Chuck Levin’s Meader.

Smith has had a profound influence on the industry, Meader says. “Back in 1985 the landscape was really different.” Some innovations were technical. “Paul came out with a vintage-style vibrato”—a bar that creates a vibrating effect when pulled—“that actually stays in tune,” says Meader. “He also made the first locking tuners.

“The whole guitar was just revolutionary, with this incredible appearance, sound, and ergonomics. It was this amazing hybrid that combined old-school hand-building tradition with a modern look and feel. It played like you had owned it for 20 years.”

Smith opened the door for other boutique manufacturers, Meader says. “A lot of guitars are built well and look good now—stores and buyers have become willing to look outside of Fender and Gibson, and it’s all because of Paul.”

Gibson didn’t like that people were buying the PRS Singlecut model, which attorneys for the Nashville-based company claimed infringed on a Gibson trademark design. Gibson filed suit in 2000, and a Nashville court issued an injunction for PRS to stop making the model. PRS appealed and won, lifting the injunction. Gibson asked the Supreme Court to intervene, but it declined in June, leaving the decision in PRS’s favor to stand.

Though annoyed by the suit, Smith says he isn’t bitter. He just wants to keep doing what he’s been doing—only more and better.

“If you open one of our guitar cases and you have that experience of ‘Wow, took my breath away!’, the guitar is going to sell,” he says. “I’ve never seen something take someone’s breath away and not sell. So if we take your breath away—lookswise, soundwise, feelwise—then we’ve done our job. I’m always looking at what we’re doing, not necessarily at what the competition is.”

Not every PRS product has been a breathtaking experience. Attempts at acoustic guitars largely went nowhere. Smith also hasn’t achieved as much as he’d like as a guitar player. But that may be changing. “My playing is just now starting to mature,” he says.

He gets up from the meeting table and digs around until he finds a CD he’s made with the five-piece rock band he’s in. Like Smith, three of the members—Mike Ault and brothers Gary and Greg Grainger—are veterans of the local music scene. Only Derek St. Holmes, formerly of Ted Nugent’s band, is an out-of-towner.

While not dazzling, Smith’s guitar work on the CD is articulate and assured. It also has, as players like to say, the tone of the gods—as it should: He was playing one of the first custom guitars PRS ever made through a rare, hand-made amplifier that goes for about $30,000.

Smith didn’t build the amp. An eccentric hermit and “amp maker to the stars” named Howard Dumble did. It’s just one of the things Smith can buy now that he’s made guitars not just for himself, but for a lot of pickers everywhere.