About Coronavirus 2020

Washingtonian is keeping you up to date on the coronavirus around DC.

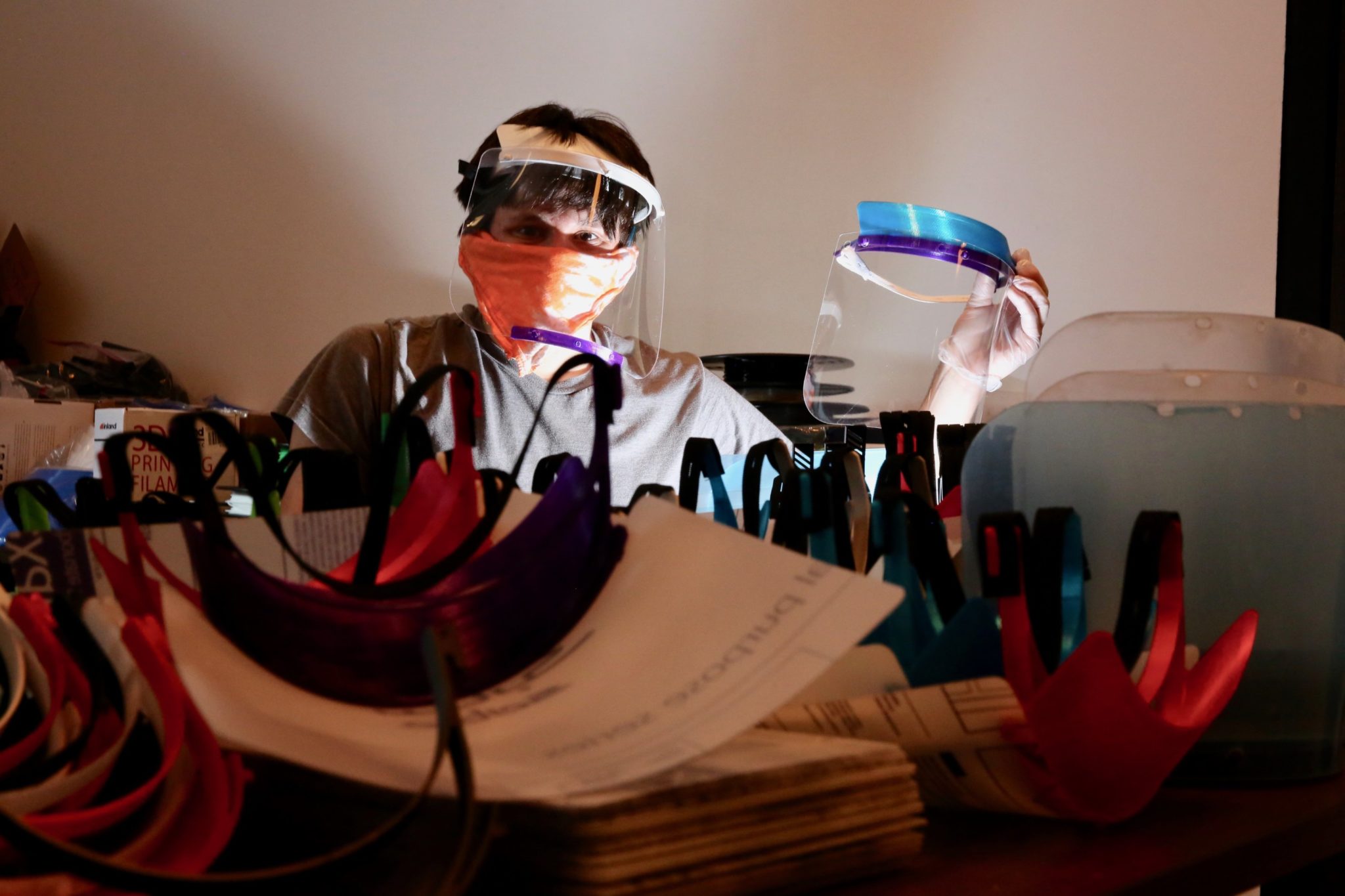

Jonah Docter-Loeb is a senior at Georgetown Day School. His Print to Protect project has corralled more than a hundred people to print and distribute medical gear for health-care workers and front-line responders. The group has made more than 3,000 parts for medical gear and delivered almost 1,500 completed face shields to local hospitals.

What made you decide to take this project on? How did it all start?

When the Covid-19 situation began to escalate in Europe and the US, I was shocked to see the lack of personal protective equipment available for medical professionals. I saw some posts online about hobbyists 3-D printing medical equipment and thought I could help make a difference. I’ve been working with 3-D printers at my high school for the past four years. When school was canceled in March, I decided to start making prints and found others in the area doing the same thing. Before long we had a group of printers of ten, then 20, and now nearly 100! The project just grew organically from the goodwill of local citizens.

How many do you want to make?

We want to help fulfill the needs of hospitals, clinics, rescue squads, and nursing homes that are running low on personal protective equipment. We want to facilitate the amazing makers we’ve been working with to keep printing until all of the need for face shields is met in the DC metro area. It is likely that US manufacturers of shields will catch up over the next few months and they will be better equipped to fill demand. We are constantly reevaluating our model, doing whatever it takes to ensure that the donations from our supporters through printtoprotect.org, and the time our volunteers put in is efficiently used to help the greatest number of people. Our operation is flexible and can adapt quickly to emerging needs as they come up to minimize waste and maximize assistance to the healthcare professionals on the front lines. Healthcare professionals must be the ones to tell us what they need if we want this operation to actually help people.

How many people are involved in this effort?

Currently, we have a team of about 75 makers who have volunteered printers to print medical gear from home. We have about 50 drivers who have volunteered to pick up the prints and drop them off at our sterilization, assembly, and distribution location at Eaton DC–a progressive hotel and gathering space which has been critical to making the project happen. We have an additional 20 people who have volunteered to assist with assembly, and people like myself who deal with the logistical sides of the operation, from design development to hospital outreach to fundraising through printtoprotect.org.

Where do the face shields go?

The majority of the shields go to hospitals in the DC metro Area. We are targeting hospitals and clinics with the greatest need—whether that be because they are in an underserved area or because they have many coronavirus patients. We have already donated them to Inova Fairfax, United Medical Center, Children’s National Medical Center, Medstar Washington Hospital Center, Holy Cross Hospital, St. Elizabeths, and Unity Health Care. The list of hospitals and clinics we have donated to will continue to grow.

Our group is also able to rapidly shift output depending on the needs of the local community. For example, we received an urgent call from DC Fire on Saturday for CPAP valve adapters, and were able to provide more than 700 parts within 48 hours.

We have also provided a few non medical grade shields to pediatrician offices and community organizers associated with the DC Mutual Aid Network.

Hospitals, clinics, nursing homes, and rescue squads looking to request medical gear should check out the forms linked on printtoprotect.org.

Who donated materials?

We are grateful to all of the volunteers and partners who are making this project possible. More than 100 local 3-D printers and volunteers have donated countless hours or labor, spools of filament, and gallons of gas making pickups and deliveries. Eaton DC has generously donated their maker space for the sterilization, assembly, and packaging process. Georgetown Day School provided significant 3-D printing resources and lent us a few 3-D printers. Carnegie Science provided communications, web, and machining resources, as well as support for materials. Trophy Mart gave us free access laser machining resources to cut the shields. We appreciate the time, money and expertise donated by all of the people and organizations who are supporting this effort.

Based on the responses of the health care professionals who’ve received our printed gear, we know we are making a difference. But there remains a huge unmet need for face shields and PPE at hospitals and clinics, rescue squads, and in nursing homes in our area. Please consider getting involved with volunteering or donating materials on our website, printtoprotect.org.

How does working on this project make you feel?

The scale of suffering brought to the world by Covid-19 is terrifying. What is heartening are the stories of people lending a hand to those marginalized and at-risk. We can only win this fight if we work together as a community. Personally, through Print to Protect, I’ve been able to ward off the feelings of boredom, isolation, and helplessness I know many of my peers are grappling with. When this is all over, I hope this unconditional empathy is transferred toward those who face similarly terrifying threats to their humanity on a day to day basis, regardless of the cause.