As mass layoffs rage on within the federal workforce, the DC area could collectively use a beer right now. Unfortunately, cracking open a locally brewed cold one is poised to get more expensive in the coming months.

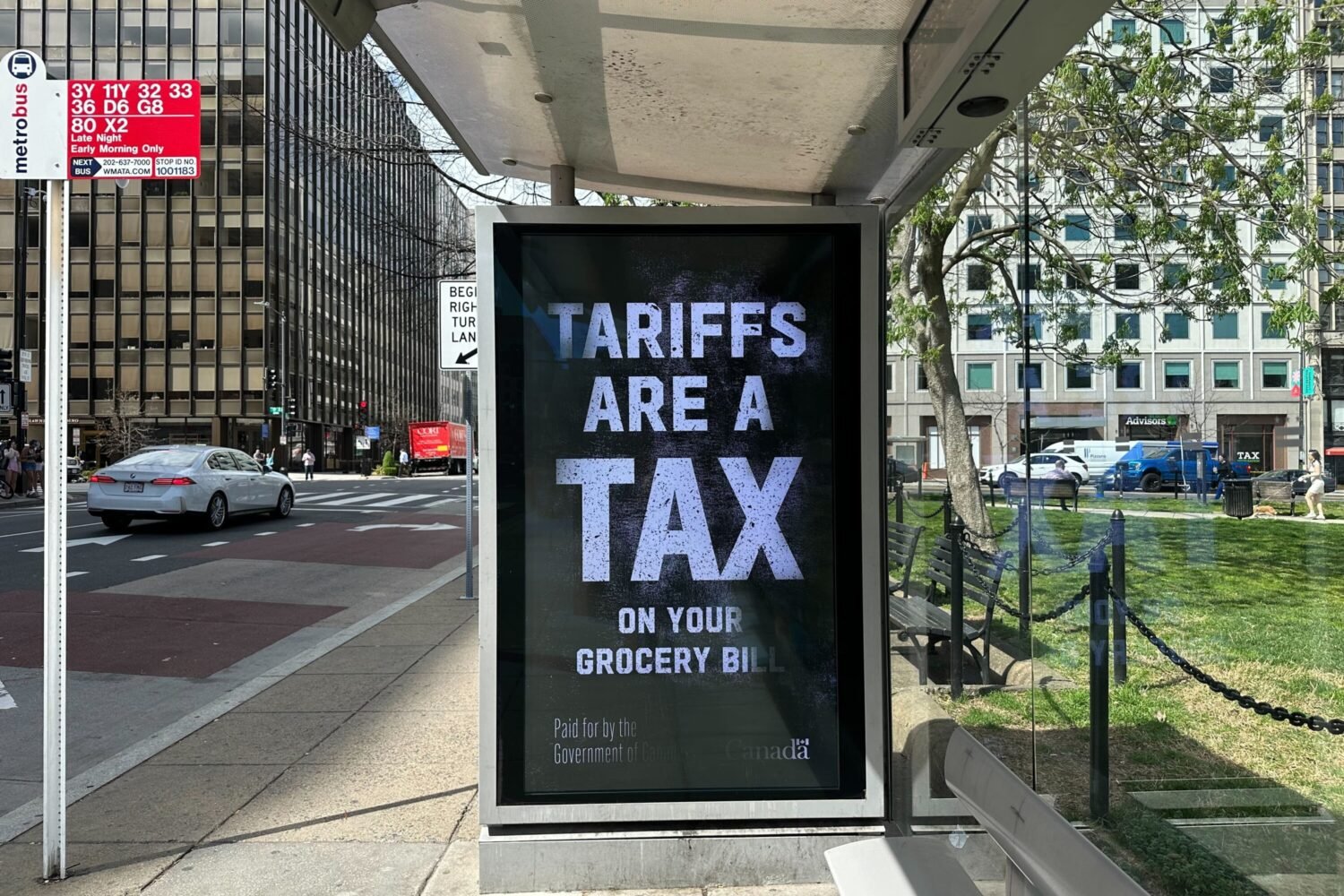

President Trump announced hefty tariffs on all imported steel and aluminum products this week. The tariffs, set to take effect in March, hark back to a similar trade policy that Trump implemented during his first term—except now, the penalties are more severe. In 2018, the US imposed a 25 percent tariff on steel and 10 percent tariff on aluminum; this time, both materials will be taxed at 25 percent. Later in his first term, Trump eventually offered exemptions to Mexico and Canada, the latter nation being America’s No.1 importer of both steel and aluminum. Those exemptions are not included in the new tariff plan.

Economists are advising US consumers to expect price hikes on all sorts of metal goods, from cars to refrigerators, as a result of these tariffs. And the industry behind one beloved American commodity in particular—brewed in steel, canned in aluminum—is already feeling the déjà vu.

Justin Cox, who owns local craft brewery Atlas Brew Works, says he is feeling “very succinctly, scared” about how the looming trade policy will affect his operations. His small business grappled with increased costs during Trump’s first-term tariffs, he says, and those measures were milder in comparison to what the president put forth this week.

In 2018, beer manufacturers across the country felt a strain thanks to increased material costs and the resulting sticker shock felt by customers. That industry-wide blow trickled down locally, causing massive disruptions. Like many other small breweries around that time, Atlas was dropped by its can vendor—an “existential” upset, according to Cox.

“It happened to a lot of small breweries because the supply got so tight that they just said, ‘You’re too little. We’re not going to sell you cans anymore,'” he says.

Eventually, Atlas was able to get back in the game by joining a co-op with other independent breweries and pooling their purchasing power. But even with the resources to manufacture, Cox anticipates that costs will skyrocket. “If these tariffs go into place and stay, it’s absolutely going to be price increases across the board,” he says. “Just general microeconomics: Drive your prices going up, and the demand is going to go down.”

Thanks to major employment shakeups in his DC-area customer base, Cox has already been losing business. Atlas’s Beer Club program lost a chunk of subscribers last month: He says loyal buyers were sending him emails to the effect of, “Hey, I need to cancel this club subscription. I just got laid off at USAID.”

With some Atlas customers tightening their belts even before the tariffs take effect, Cox is steeling himself for the impact that increased manufacturing costs—and thus, higher prices—could have on the brewery’s livelihood. Unlike its big-name competitors, Atlas doesn’t have enough inventory space to keep years’ worth of empty cans in stock for a rainy day. “We’re able to keep about six months or so,” Cox says. “We’re much more vulnerable to price fluctuations due to that.”

Cox estimates that jacked-up steel and aluminum prices will drive Atlas’ production costs up about 20 percent for each case of canned beer. Why not switch to glass bottles? Packaging decisions are made and more or less finalized early on in the process of opening a brewery, Cox says. Not only would it be expensive to install a bottling line now, but Atlas just doesn’t have enough physical real-estate to accommodate one. According to Cox, that pivot wouldn’t be totally “off the table,” but he estimates the changes would take at least a year to implement.

Already, District beer drinkers across the board tend not to buy local. “The entire DC brewing scene accounts for maybe 2.5 percent of the beer that’s sold in DC,” Cox says. And alcohol sales have been on the decline in general as consumers grapple with inflation—2024 marked the first time in 20 years that more craft breweries shuttered than opened. Even shoppers who are willing to shell out any extra money on beer are less inclined to opt for their neighborhood craft option.

“If you’re in the grocery store and you’re looking at the beer shelf and there’s 99 different beers, and you see the Atlas six-pack and it’s $2 more than the Sierra six-pack or whatever it may be—the consumer is not thinking, ‘Oh, they must be impacted by these tariffs and their supply chain. Three people upstream from them are having to pay more for this raw material,'” Cox says. “It almost feels like it’s Atlas’s fault, but an increase in price is not going into our pocket. That’s just going out the door and up the chain to pay for these tariffs.”