The meal that changed my thinking about the future of food was an unexpectedly delicious three-course lunch not long ago. It began with a marvelously crispy puff pastry filled with a delicate shrimp curry, continued with a luscious lobster mac and cheese, moved on to a plate of short ribs so tender they seemed to have been slow-cooking for days, and concluded with a light and perfect soufflé.

I wasn’t luxuriating in the dining room of a celebrity chef or indulging my tastes at the hottest gastrobistro—I was sitting in a white-walled lab.

Had I been blindfolded, I never would have guessed that my lobster mac and cheese hadn’t been prepared and cooked on the spot but rather reheated in an immersion bath after exiting its vacuum-sealed bag. Or that my short ribs had been in a hot pan for a matter of minutes. Or that my soufflé had begun life in a canister, its lab-manufactured contents slipped from the tube like refrigerated dough, cut into a hockey-puck-size disk, placed in a ramekin, and baked for 12 minutes.

How could these dishes all be so flavorful and precise? How could something that suggested the starship Enterprise conjure Joël Robuchon?

Spain and its chefs have been hailed in many quarters as the future of cooking, but the “molecular gastronomy” pioneered by that country is still largely a cult phenomenon among the elite, a dazzling indulgence for jaded cooks and foodies alike. If you want to understand where food in the 21st century is headed, you have to understand what’s taking place at a plant in an Alexandria industrial park.

The emergence of Cuisine Solutions—and its growing power and prominence—seems to astonish even its founders.

What it is today is not what it was a decade ago. Back then, producing dinners for the airline industry was its primary mission, and the company maintained a relatively low profile. Then came September 11. The temporary shutdown of air travel necessitated a shift in emphasis, so Cuisine Solutions began pitching chefs and restaurateurs on the value of sous-vide—a process by which meats, fishes, sauces, and purées can be vacuum-packed and then cooked in an immersion bath at a low temperature.

Sous-vide isn’t a new idea but rather an old one with new and potentially startling applications. Bruno Goussault, Cuisine Solutions’ chief scientist, developed the method in 1970 during his stint at the Sepial research lab in France, where he was working on combatting malnutrition in Niger and Senegal. One day, a chef came to him for help: Could the food scientist help him prepare a more tender roast beef?

Goussault set to work. He later published a scientific paper explaining sous-vide and began consulting with companies. One was a bakery chain, Vie de France, which was struggling to arrive at a new method of thaw-and-bake. Stanislas Vilgrain, Vie de France’s CEO, was so impressed with Goussault and his application of scientific methods in culinary problem solving—which portended a new direction for the bakery—that he opened a small sous-vide plant in France in the late ’80s. The Alexandria plant followed in 1990. Eventually, the new direction supplanted the old direction: Vie de France opened a plant in Chile, another in France, and Cuisine Solutions was born.

Sous-vide didn’t gain wider acceptance until Goussault arrived at the Alexandria lab in 2001, joining Gerard Bertholon, a former two-star Michelin chef. A battalion of two dozen talented cooks—some of them having exchanged their white toques for the see-through hairnet demanded of factory work—puts the vision into practice.

In the years since, Goussault has trained many of America’s greatest chefs—and 45 of the 56 Michelin-starred chefs—in using sous-vide. Multitasking talents such as Charlie Trotter, Daniel Boulud, and Thomas Keller are taking advantage of the process, which combines art (long cooking) and science (mathematical precision), to market their names and become brands.

The lobster mac and cheese I ate is one of Keller’s signature dishes and a bestseller in the Cuisine Solutions’ FiveLeaf gourmet frozen-foods line. Keller’s lobster mac and cheese—like Trotter’s lamb sirloin and Boulud’s braised lamb shank—is mass-produced, packaged, and shipped to grocery megastores, gourmet markets, and some wine stores. Locally, you can buy them at Costco and at Paul’s Discount Wine & Liquor in DC. The boxes look no different from most TV dinners. To the uninitiated, it would be easy to presume they were just some fancy-pants version of Swanson’s.

They are and they aren’t.

The idea of the greatest chefs in the country collaborating with a science lab on a line of boil-in-the-bag dinners is confounding to many food lovers. We live, after all, in an age of unprecedented awareness and activism, when subscribing to the sanctity of local, seasonal, and sustainable has come to be regarded as a moral act and saying no to food processing and engineering a political one. Cuisine Solutions frozen dinners seems to stand, for some, as one of the ills of the brave new world of food. Many foodies are firm in their belief that no reheated dishes can compare to the satisfactions of a good restaurant meal, or to a good homecooked meal.

But here’s what they won’t say: The quality of these gourmet frozen dinners is so high that it would be hard for many people to tell the difference between them and a dinner at a good restaurant.

Should we be troubled by this?

We should and we shouldn’t.

Call it the law of unintended gastronomic consequences.

The Cuisine Solutions lab didn’t set out to change the industry. But its remarkable success in helping chefs replicate intricate and refined dishes on a large scale has opened up many possibilities for the industry, knocking down the boundaries between fast food and fine dining.

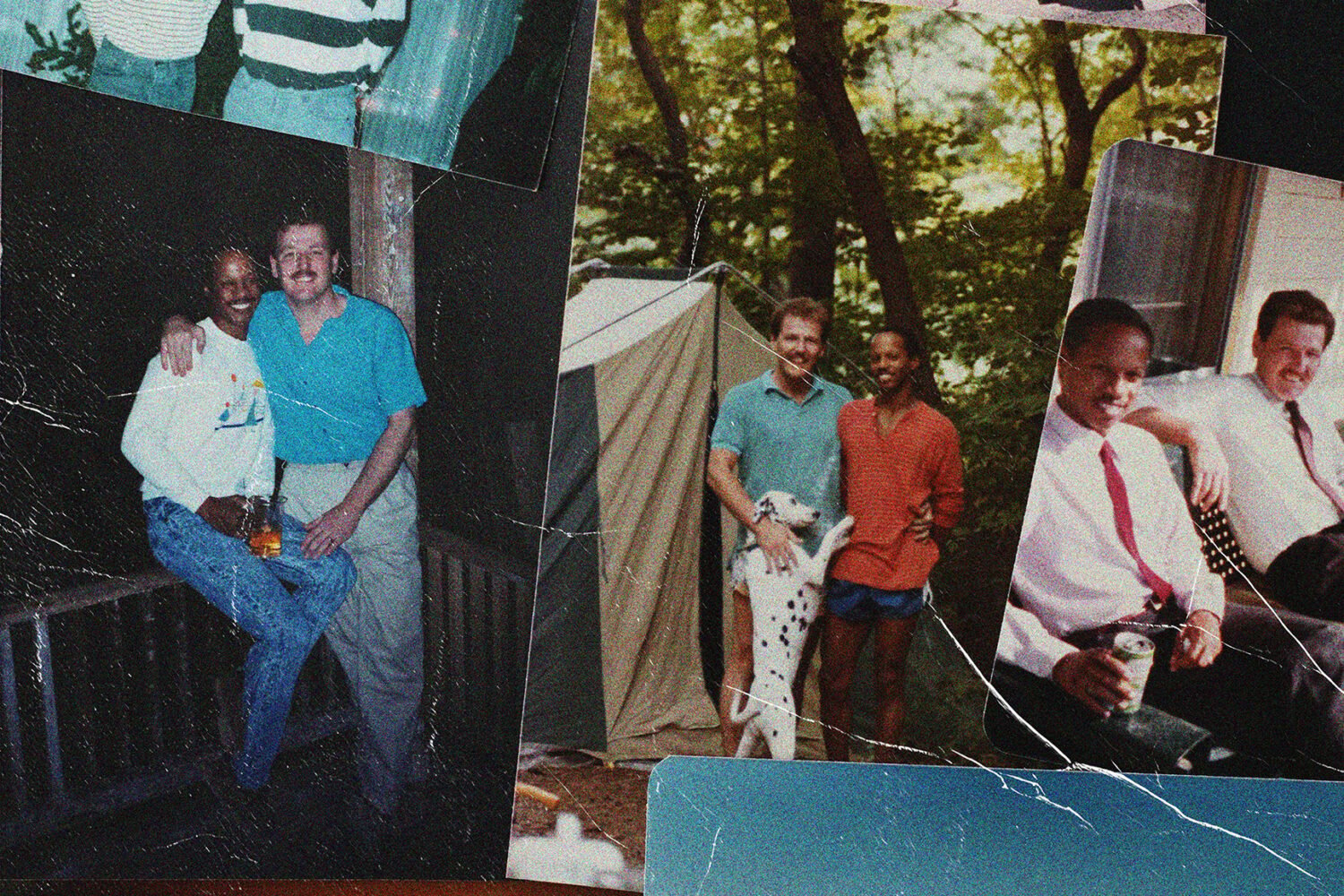

Bruno Goussault, Bruno Bertin, and Michel Richard ponder the implications of the new technology over glasses of wine. Photograph by Scott Suchman

The half chicken and lobster sauce on a special menu at T.G.I. Friday’s are sent to the lab, but so are the beef cheeks at Central Michel Richard in DC. Richard, one of the world’s most brilliant chefs, operates his own immersion bath at Citronelle, his flagship, but not at the more casual Central, so he packs his prime-beef medallions off to Cuisine Solutions. The meat cooks at 130 degrees for a couple of days before returning to the restaurant, where it’s finished on the grill and served alongside a twirl of tagliatelle. Richard explains his decision to outsource much of the cooking of one of Central’s most popular dishes to the lab as not much of a decision at all: “Better technology, perfect equipment, very precise.”

The calculus for today’s chef has changed, says Mark Bucher, an adviser for Cuisine Solutions who also operates three outlets of BGR the Burger Joint, for which he outsources his turkey burgers, hoping to avoid the trap of dry meat: “As a chef, you’ve got to be able to deliver products that can wow customers when you’re not there.”

And there are so many variables that chefs can’t control, such as inconsistent ovens and burnout line cooks. A water bath, on the other hand, is always the same—a reassuring thought for a peripatetic chef like Wolfgang Puck, who controls the strings on a vast food empire (the Source in DC is among his many properties) and can’t be everywhere at once.

“Wolfgang Puck could not be where he is today without Cuisine Solutions,” says Bucher, referring to the Austrian superchef’s ubiquitous presence in America’s airports. The lab enabled him to translate his dishes for mass consumption.

Precision and repetition on a large scale is what brought José Andrés, the DC-based restaurateur with a TV show and operations here and in Los Angeles, to Cuisine Solutions. Andrés is now consulting for a number of Spanish tapas bars in Spain and on the West Coast, and he has enlisted the lab’s help in streamlining some of his products.

Chefs without far-flung empires are turning to the lab for help with their high-end catering. “When Daniel Boulud does an event and needs 900 lamb shanks in a couple of days,” says Bucher, he calls Cuisine Solutions. Why? “Because he just doesn’t have the bandwidth to store it all, and he knows that, one, he can save time by going to Bruno and getting the precooking out of the way and, two, he can get those shanks just the way he wants them.” There are 24 water tanks at the plant in Alexandria, and each can be customized; if Boulud wanted, he could cook 24 different versions of his lamb shanks at once.

A Boulud disciple, Bertrand Chemel, now the chef at 2941 in Falls Church, turned to Cuisine Solutions recently for help with a braised-beef-short-rib dish that was featured on both a banquet menu and a Restaurant Week menu. Having been trained in the technology at Daniel, Boulud’s celebrated Manhattan restaurant, Chemel wasn’t just familiar with the immersion-bath process but also comfortable with it. He understood its uses, particularly in subduing tougher cuts of meat. With his standard menu, he liked having total control over every operation in the kitchen, but at high volume it was hard to resist the allure of outsourcing the short ribs to the lab.

This same rationale appeals to the overtaxed kitchens of the area’s Hilton, Marriott, and Gaylord properties, where galas for thousands are the norm. The lab’s technology—with its promise of a new, improved variation of the boil-in-the-bag cooking that has long defined the rubber-chicken circuit—is no longer just a luxury, a tool to experiment with; increasingly, it’s becoming a necessity.

The fast-food giant Chipotle was among the first to realize the lab’s potential value. Ever wonder about the uncanny quality and consistency of the long-cooked morsels of pork, chicken, and steak tucked into all those thousands of burritos and tacos? Representatives of the chain were schooled in the particulars of the sous-vide method by the Alexandria lab at a seminar. It wasn’t much later that Chipotle decided to eliminate the middle man and built its own large-scale, immersion-bath-based lab to assist in the high-grade mass production of its chicken and rice and beans.

Bucher believes the day isn’t far off when we’ll see the first lab-centered restaurant. He cites the example of the chain Panera Bread, which has no kitchen equipment yet produces a salmon club and grilled-salmon salad, both with the help of Cuisine Solutions.

“I could totally see a restaurant with no kitchen, really,” Bucher says, “just a small storage area and everything coming in in bags and being reheated and finished on a small grill. You look at the success of some of the food carts, working in such tight quarters, and it’s not so far-fetched. Plus, the quality is there. You can taste it.”

But even as the most enthusiastic proponents of the technology embrace its many uses, they’re increasingly leery of diners learning of their enthusiasm. Leery of customers seeing them as ceding control of their craft—a craft that, for all its advances, is rooted in tradition and that demands of its practitioners a passionate, hands-on devotion.

Daniel Boulud, I learned during my research, was antsy about this story. Many at the lab are a little on guard, too—welcoming the attention but uneasy with the prospect of being outed for playing such a role. The job of those who work behind the scenes, after all, is to make the chefs look good, not compete for the spotlight.

Michel Richard went so far as to request an advance copy of this article—underscoring his uneasiness with being portrayed as an avatar of the new technology.

I was unpersuaded, but weeks earlier, over the phone, he had made a convincing case to me for the lab’s role in his world. I didn’t hear a chef in thrall to a new toy; instead Richard spoke with a disarming humility and openness, particularly for someone so celebrated. The lab wasn’t an appendage to his kitchens—it was a full-fledged partner in his operations, a creative accomplice.

“It is,” he said, “a part of my mind when I create new dishes now. I will still use the old style of cooking—sautéing, braising, baking, roasting. But why not take advantage of the new tools?”