The 10 percent tariff President Trump plans to implement on imported aluminum next week may excite his economic-protectionist base. But if the new policy goes through, it might have the direct effect of making your beer more expensive, both at the mass-market and craft level.

Already, Washington’s craft brewers are bracing for some hairy times. “Higher aluminum prices via tariffs will absolutely negatively affect Atlas and other craft breweries,” says Justin Cox, the founder of DC’s Atlas Brew Works.

Beer is one of the industries most likely to be directly impacted by new aluminum tariffs, owing to the massive quantities of the beverage shipped in cans. MillerCoors, the second-largest US brewer, was quick to criticize Trump’s decision, writing in a series of tweets that the tariff is likely to cause aluminum prices to rise and the brewing industry to cut jobs.

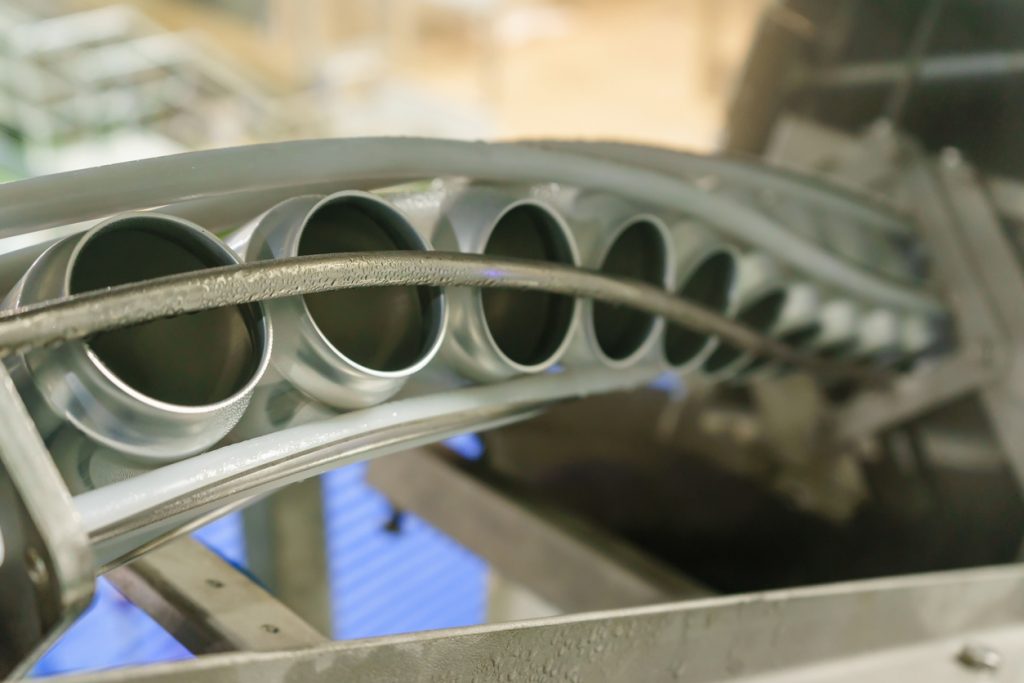

The losses could be even more acute for craft brewers. Even though 98 percent of canning aluminum used by the US beer industry is produced domestically, hiking up prices on imported aluminum will make the overall manufacturing process more expensive, says the Brewers Association, the trade group for craft beer makers. And even though craft beer might be more synonymous with intricately designed glass bottles, more and more brewers, like Atlas, are shipping their products in cans. As of 2016, more than 40 percent of all beer from breweries that produce less than 100,000 barrels per year—a group that includes all but the 30 or so largest brewers—was packaged in cans, according to the Brewers Association.

The share of all craft beer arriving in cans is growing, too, reaching nearly 30 percent of all packaged beer by the end of 2017, according to Bart Watson, the Brewers Association’s resident economist. One of the biggest reasons behind cans’ growing popularity, Watson wrote last month, is that they’re used more often by the fastest-growing breweries. There’s also been a change in beer-drinkers’ behavior, with craft aficionados realizing that cans aren’t just conveyances for mass-market suds.

But aluminum, even before the new tariffs, is already a significant expense for brewers. Cox estimates the material accounts for at least 20 percent of the cost of a case of Atlas’s beer. “The minimum order on cans is already a massive cash outlay for a small business, and any raise in the cost of cans will be immediately felt,” he says.

Switching to glass bottles is an unrealistic solution. Atlas has already made significant investments in canning equipment, and converting to bottling lines would set the brewery back at least $500,000, Cox says. Aluminum cans are also less expensive to ship, because they’re lighter, and are made primarily from recycled material. (About 70 percent of the metal in canning aluminum comes from recycled cans and scrap metal.)

Assuming Trump doesn’t suddenly recant his decision, Cox says Atlas will go into a bit of a holding pattern until it figures out how much the new tariffs will cost the company. “We will not be making hiring decisions on new staff or investing in new brands going into cans until we are able to figure out how to adsorb the increased cost, either by raising prices or cutting back on labor costs,” he says.

Atlas currently has an open position for a warehouse manager at its Northeast DC brewery, and while Cox is interviewing candidates, it might have to go unfilled. “Hopefully we will still be able to make the hire at all but that is uncertain right now.”